YC series permanent lifting magnet and permanent magnetic lifters are made of high-energy magnetic material adopting scientific magnet circuit theory-featuring huge attraction force, compact, light dead-weight and convenient and safe for operation. They features strong attraction, smaller volume, lighter weight, powerful lifting effect, easy and safe to operate, long-period effort, an ideal energy-economizing lifter and are more convenient than the electromagnetic lifter to transfer the normal temperature steel plates in ship-making industry, engineering mechanical industry, automobile industry and so on. We provide series of permanent lifting magnets YC1, YQA, YQB, YQC, YQD, YQE, YX2, YX3 and YC4 according to the modes of material unloading.

Series YC1 is used for manually handling small steel plates materials and round pieces; series YQA, YQB, YQC, YQD and YQE permanent magnet lifters are used to lift and transport the steel and iron for factories, docks, ware houses, transportation and so on; series YX2 is used for lifting short and thick steel plate using ratchet wheel unit to hold and release the materials in auto cycle; series YX3 is used for manually handling long and thin steel plates in combined units. The level type structure can guarantee the unit to be operated in synchronism. Series YC4 is used for handing large, irregular and heavy-forging steel plate and casting blank. The design of magnetic road and unloading structure is very unique to ensure our lifting magnets can control the switch state of the crane's magnetic road by controling the main hook up and down, and also by adopting electrical mode. Please notify us the "power-driven" you need when sending an enquiry.

Series YPL are used for lifting, handling and laying of various Ferromagnetic workpieces. They are widely used in the different industries including steel machining, mold and so on. They feature the characterisics of light weight, large hoisting capacity, easy for lift and operate, long serve life, zero maintenance and so on. Besides, their magnetic circuit design is unique and the value of remanence is nearly zero. The safety coefficient is high and the maximum pull out force is 3.5 times more than the rated lifting force. A safety switch button is installed on the handle, which could be operated by one hand conveniently and safely. The "V" groove design on the bottom enable the magnetic lifter to lift corresponding round steel and steel plate. During working, no electric power is needed and the magnetic force is permanent and never disappear, safe for using.

Lifting capacity

Design code

Permanent-magnet lifter

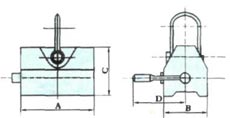

| Model | overall dimension (mm) | m (kg) Mass | Lifting Capacity (kg) | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| YC1-0.2 | 130 | 110 | 124 | 250 | 12 | 200 |

| YC1-0.3 | 180 | 110 | 124 | 270 | 16 | 300 |

| YC1-0.5 | 258 | 110 | 124 | 380 | 25 | 500 |

| YC1-1 | 263 | 180 | 219 | 412 | 68 | 1000 |

| YC1-2 | 388 | 220 | 269 | 552 | 150 | 2000 |

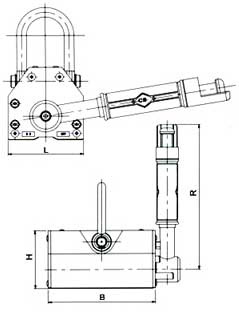

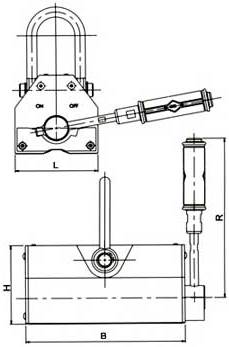

| Model | Rated lifting strength (kgf) | Cylindrical lifting strength (kgf) | Max pull-off strength (kgf) | L | B | H | R | Operation temperature (°C) |

Dead Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| YQ100A | 100 | 50 | 350 | 64 | 92 | 67 | 107 | < 80 | 3.0 |

| YQ300A | 300 | 150 | 1050 | 92 | 162 | 91 | 155 | < 80 | 7.5 |

| YQ600A | 600 | 300 | 2100 | 122 | 233 | 118 | 196 | < 80 | 23.0 |

| YQ1000A | 1000 | 500 | 3500 | 179 | 268 | 164 | 255 | < 80 | 55.5 |

| YQ2000A | 2000 | 1000 | 7000 | 234 | 378 | 212 | 426 | < 80 | 125.0 |

| YQ3000A | 3000 | 1500 | 10500 | 310 | 497 | 252 | 505 | < 80 | 220.0 |

| YQ6000A | 6000 | 3000 | 21000 | 442 | 621 | 210 | 548 | < 80 | 440.0 |

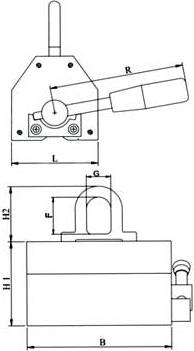

| Model | Rated lifting strength (kgf) | Cylindrical lifting strength (kgf) | Max pull-off strength (kgf) | L | B | R | H1 | H2 | F | G | Operate Temp. (°C) |

Dead Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| YQ100B | 100 | 50 | 350 | 64 | 92 | 148 | 67 | 54 | 35 | 28 | < 80 | 3.0 |

| YQ300B | 300 | 150 | 1050 | 92 | 162 | 180 | 91 | 70 | 47 | 40 | < 80 | 7.5 |

| YQ600B | 600 | 300 | 2100 | 122 | 233 | 185 | 118 | 95 | 64 | 50 | < 80 | 23.0 |

| YQ1000B | 1000 | 500 | 3500 | 179 | 268 | 210 | 164 | 95 | 64 | 50 | < 80 | 55.5 |

| YQ2000B | 2000 | 1000 | 7000 | 234 | 378 | 365 | 212 | 120 | 80 | 60 | < 80 | 125.0 |

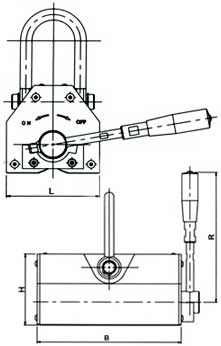

| Model | Rated lifting strength (kgf) | Cylindrical lifting strength (kgf) | Max pull-off strength (kgf) | L | B | H | R | Operation temperature (°C) |

Dead Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| YQ100C | 100 | 50 | 350 | 64 | 92 | 67 | 107 | < 80 | 3.0 |

| YQ300C | 300 | 150 | 1050 | 92 | 162 | 91 | 207 | < 80 | 7.5 |

| YQ600C | 600 | 300 | 2100 | 122 | 233 | 118 | 247 | < 80 | 23.0 |

| YQ1000C | 1000 | 500 | 3500 | 179 | 268 | 164 | 275 | < 80 | 55.5 |

| YQ2000C | 2000 | 1000 | 7000 | 234 | 378 | 212 | 370 | < 80 | 125.0 |

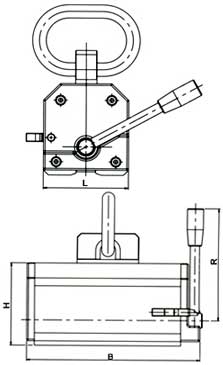

| Model | Rated lifting strength (kgf) | Cylindrical lifting strength (kgf) | Max pull-off strength (kgf) | L | B | H | R | Operation temperature (°C) |

Dead Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| YQ100D | 100 | 50 | 350 | 64 | 92 | 67 | 148 | < 80 | 3.0 |

| YQ300D | 300 | 150 | 1050 | 92 | 162 | 91 | 180 | < 80 | 7.5 |

| YQ600D | 600 | 300 | 2100 | 122 | 233 | 118 | 185 | < 80 | 23.0 |

| YQ1000D | 1000 | 500 | 3500 | 179 | 268 | 164 | 210 | < 80 | 55.5 |

| YQ2000D | 2000 | 1000 | 7000 | 234 | 378 | 212 | 365 | < 80 | 125.0 |

| Model | Rated lifting strength (kgf) | Cylindrical lifting strength (kgf) | Max pull-off strength (kgf) | L | B | H | R | Operation temperature (°C) |

Dead Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| YQ100E | 100 | 50 | 350 | 64 | 114 | 65 | 136 | < 80 | 3.0 |

| YQ150E | 150 | 75 | 450 | 60 | 147 | 65 | 136 | < 80 | 3.5 |

| YQ200E | 200 | 100 | 750 | 80 | 140 | 85 | 136 | < 80 | 6.0 |

| YQ300E | 300 | 150 | 1050 | 80 | 170 | 91 | 136 | < 80 | 9.5 |

| YQ500E | 500 | 250 | 1750 | 100 | 225 | 110 | 150 | < 80 | 16.0 |

| YQ1000E | 1000 | 500 | 3500 | 176 | 300 | 165 | 285 | < 80 | 58.0 |

| YQ2000E | 2000 | 1000 | 7000 | 200 | 400 | 210 | 335 | < 80 | 116.5 |

| Model | Rated lifting strength (kg) | Length (mm) | Width (mm) | Height (mm) | Dead Weight (kg) |

|---|---|---|---|---|---|

| YPLM-300 | 300 | 205 | 90 | 90 | 11 |

| YPLM-600 | 6600 | 276 | 115 | 106 | 19 |

| YPLM-1000 | 1000 | 310 | 150 | 135 | 43 |

| YPLM-1500 | 1500 | 380 | 172 | 152 | 68 |

| YPLM-2000 | 2000 | 425 | 180 | 160 | 95 |

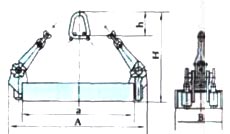

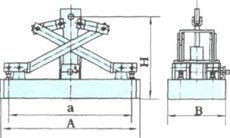

| Model | Lifting Capacity (kg) | Min.Holding Material Contour L×W(mm) | overall dimension (mm) | Mass (kg) |

||||

|---|---|---|---|---|---|---|---|---|

| A | a | B | H | h | ||||

| YX2-0.2 | 200 | 440×185 | 440 | 350 | 185 | 525 | 112 | 50 |

| YX2-0.5 | 500 | 560×275 | 560 | 470 | 275 | 645 | 112 | 80 |

| YX2-1 | 1000 | 720×355 | 720 | 540 | 355 | 760 | 165 | 140 |

| YX2-2 | 2000 | 870×436 | 870 | 690 | 436 | 905 | 165 | 235 |

| YX2-3 | 3000 | 1100×436 | 1100 | 950 | 436 | 1090 | 180 | 410 |

| YX2-5 | 5000 | 1270×565 | 1270 | 1010 | 565 | 1130 | 220 | 640 |

| YX2-10 | 10000 | 1270×1100 | 1270 | 1010 | 1100 | 1480 | 350 | 1450 |

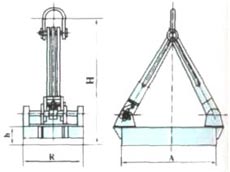

| Model | Lilting Capacity (kg) | Min. Holding Material Contour L×W (mm) | Overall Dimension (mm) | Mass (kg) |

|||

|---|---|---|---|---|---|---|---|

| A | a | B | H | ||||

| YX3-0.5 | 500 | 716×196 |

716 620 |

196 | 460 | 120 | |

| YX3-1 | 1000 | 824×256 | 824 | 586 | 256 | 570 | 240 |

| YX3-2 | 2000 | 960×376 | 960 | 848 | 376 | 600 | 320 |

| YX3-3 | 3000 | 960×406 | 960 | 848 | 406 | 680 | 420 |

| Model | YC4-1 | YC4-2 | YC4-3 | YC4-5 | YC4-10 | YC4-20 | YC4-30 | YC4-40 | YC4-50 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Overall Dimension (mm) | A | 550 | 625 | 690 | 970 | 1440 | 1640 | 1950 | 2410 | 2410 |

| B | 350 | 460 | 470 | 580 | 800 | 800 | 1060 | 1060 | 1220 | |

| h | 105 | 110 | 120 | 130 | 155 | 260 | 310 | 310 | 310 | |

| H | 518 | 672 | 806 | 1020 | 1440 | 1560 | 1890 | 2310 | 2338 | |

| Mass (kg) | 130 | 250 | 386 | 575 | 1197 | 2110 | 3730 | 4610 | 5370 | |

| (kg) Lifting Capacity | 1000 | 2000 | 3000 | 5000 | 10000 | 20000 | 30000 | 40000 | 50000 | |