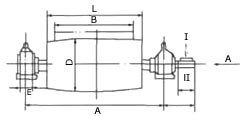

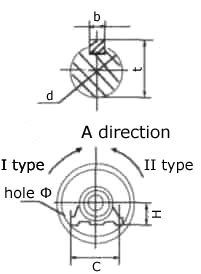

RCTG series permanent magnetic pulleys appearance size and installation size sketch map

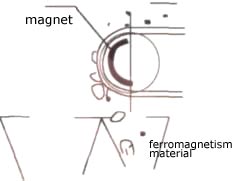

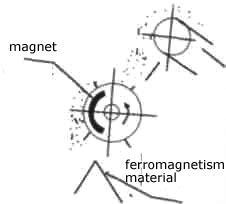

Permanent magnetic pulleys are ideal magnetic products used as head pulleys in belt conveyors for removing ferrous contaminants from material flow. The magnetic field of the pulley attracts the ferrous fines which are held to the belt until it reaches the underside. The separated ferrous materials pass out of the the magnetic field and are collected separately into a chute or bin. The cleaned material is discharged normally over the pulley in a vertical drop. The magnetic conveyor head pulleys are available in various sizes to meet requirements of most conveyor system. The permanent-magnet wheel is suitable for purification treatment of removing iron and fines coming from the conveyer system used in coal mining industry,power industry and sugar refining industry, and for recovery of the steel dregs and iron removing from the sugercane dregs in sugar refining factory.

RCTG series permanent magnetic pulleys suit for using in separating iron in transport system of coal, powder, sugar industries and so on. It can purify deal with powder material, retrieve use steel dregs which can prevent grinders, crushers and squeezer from damaging and wearing. The equipment is widely used in metallurgical, mining, powder, sugar, chemical, glass, papermaking, buildingmaterials, food industries etc.

The series magnetic pulleys can be used in various environments, they can be installed easily at conveyor discharge and easy for maintenance, feature stable magnetic field, strong magnetism, may work continuously, auto-discharging iron, simple to operate, needn't control power source.

The series magnetic pulleys won appraisal of Jinangsu province in 1992. The functions are better comparing to the same equipment of domestic, and reach advanced level of home and abroad. It may satisfy the using need of high magnetic field strength and deeper getting rid of iron.

| Model | B | D | A | L | C | E | F | I | H | d | b | t | Hole Φ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCTG-50/50 | 500 | 500 | 850 | 600 | 350 | / | 223.5 | 100 | 120 | 60 | 18 | 64 | 24 |

| RCTG-50/65 | 650 | 500 | 1000 | 750 | 350 | / | 223.2 | 100 | 120 | 60 | 18 | 64 | 24 |

| RCTG-50/80 | 800 | 500 | 1300 | 950 | 350 | / | 223.5 | 100 | 120 | 60 | 18 | 64 | 24 |

| RCTG-63/65 | 650 | 630 | 1000 | 750 | 380 | 80 | 223.5 | 135 | 140 | 90 | 25 | 95 | 28 |

| RCTG-63/80 | 800 | 630 | 1300 | 950 | 380 | 80 | 296 | 175 | 140 | 90 | 25 | 95 | 28 |

| RCTG-63/100 | 1000 | 630 | 1500 | 1150 | 380 | 80 | 296 | 175 | 140 | 90 | 25 | 95 | 28 |

| RCTG-63/120 | 1200 | 630 | 1750 | 1400 | 440 | 90 | 365 | 215 | 160 | 110 | 36 | 118 | 34 |

| RCTG-80/80 | 800 | 800 | 1300 | 950 | 380 | 80 | 296 | 175 | 140 | 90 | 25 | 95 | 28 |

| RCTG-80/100 | 1000 | 800 | 1500 | 1150 | 440 | 90 | 365 | 215 | 160 | 110 | 36 | 118 | 34 |

| RCTG-80/120 | 1200 | 800 | 1750 | 1400 | 440 | 90 | 365 | 215 | 160 | 110 | 36 | 118 | 34 |

| RCTG-80/140 | 1400 | 800 | 2000 | 1600 | 440 | 90 | 365 | 215 | 160 | 110 | 36 | 118 | 34 |

| RCTG-80/160 | 1600 | 800 | 2200 | 1800 | 480 | 100 | 431 | 255 | 180 | 130 | 36 | 138 | 34 |

| RCTG-80/180 | 1800 | 800 | 2400 | 2000 | 480 | 100 | 431 | 255 | 180 | 130 | 36 | 138 | 34 |

| RCTG-100/100 | 1000 | 1000 | 1500 | 1150 | 480 | 100 | 431 | 255 | 180 | 130 | 36 | 138 | 34 |

| RCTG-100/120 | 1200 | 1000 | 1750 | 1400 | 480 | 100 | 431 | 255 | 180 | 130 | 36 | 138 | 34 |

| RCTG-100/140 | 1400 | 1000 | 2000 | 1600 | 540 | 110 | 465 | 275 | 200 | 150 | 45 | 160 | 34 |

| RCTG-100/160 | 1600 | 1000 | 2200 | 1800 | 540 | 110 | 465 | 275 | 200 | 150 | 45 | 160 | 34 |

| RCTG-100/180 | 1800 | 1000 | 2400 | 2000 | 540 | 110 | 465 | 275 | 200 | 150 | 45 | 160 | 34 |

| RCTG-100/200 | 2000 | 1000 | 2600 | 2200 | 590 | 120 | 535 | 335 | 170 | 150 | 45 | 180 | 40 |

| RCTG-100/220 | 2200 | 1000 | 2900 | 2200 | 590 | 120 | 535 | 335 | 170 | 150 | 45 | 180 | 40 |