This product series is applicable to furnace cupola and electric furnace for automatic weighing and distributing the metal material such as new foundry ingot,returning iron,waste steel and etc,It ensures stable quality of molten iron and good operation effect: the temperature of molten iron generally increases 10-20℃;the fluctuation ratio of carbon -bearing capacity keeps below 0.1% ;the waste product ratio drops 2 -5% ;the furnace material and energy consumption are reduced by 2-5% and the labor power is saved.

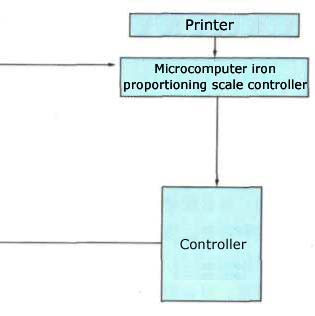

Automatic constant burden.The max. eight different furnace materials can be distributed put batch and up to 999 batches.Burden error can be am compensated batch by batch avoiding accumulated errors; Out of tolerance alarm to ensure the accurate burden with average error of continuous burdens (5 batches) less than 3%;Quick burden distributing speed.The average burden (5 batches) distributing time is no more than 16-20 seconds; Auto -printed record card,burden distributing time per batch,burden loading interval,batch NO..furnace material actual weight.weight per batch and accumulated burden weight; Using colorful membrane switching panel with wide liquid crystal screen Chinese display;Chinese menu input; audible alarm and acoustooptical alarm;Data protection at power failure to ensure the important data will never it lost.RS232 interface (also connecting RS485 interface) and multi channel switching input & output interfaces availalble;Using pull type high strength anti-shock sensors series BLR (or RST);Manual digital display function available.

There are two installation modes:installed ground control chamber or the driving cabin,of the crane The microcomputer iron proportioning scale should be protected for anti-shock and anti-dust.

| Complete Equipment Model |

Corollary equipment | Average burden error | Average burden sistributing time (second) |

Furnace cupola applied | ||||

|---|---|---|---|---|---|---|---|---|

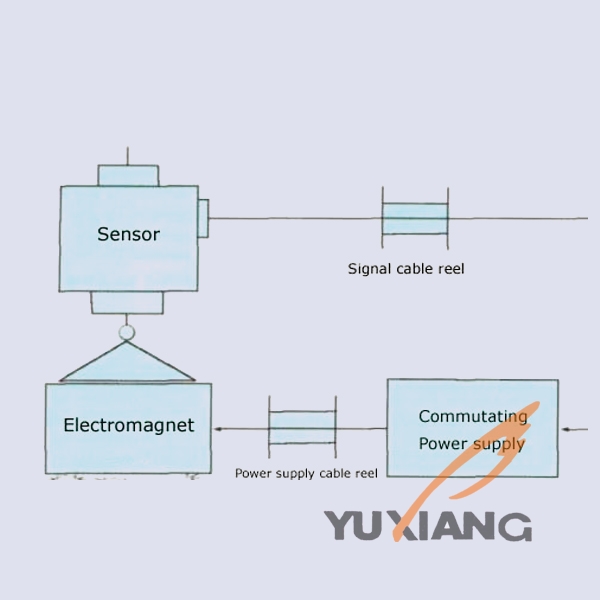

| Magnetic disk digital electronic scale | Sensor | Universal hook | Electromagnet | Commutating power supply | ||||

| Y573B | WPT-250A | BLR-1t | WXG-1 | MW5-70L/1 | WZK-25A | 2% | 15 | <5t/h |

| Y575B | WPT-500A | BLR-1.5t | WXG-3 | MW5-90L/1 | WZK-50A | 3% | 16 | 5t/h |

| Y577B | WPT-750A | BLR-3t | WXG-3 | MW5-110L/1 | WZK-50A | 3% | 18 | 5t/h-7t/h |

| Y5710B | WPT-1000A | BLR-5t | WXG-5 | MW5-130L/1 | WZK-75A | 4% | 20 | 7t/h-10t/h |

| Y5715I! | WPT-1500A | BLR-7t | WXG-10 | MW5-150L/1 | WZK-100A | 45 | 24 | 10t/h-15t/h |