We offer the best quality Magnetic Roll Separators, which are machined using refined quality raw materials to ensure high performance of products and customers satisfaction.

Our magnetic roll separator can select waterish powders that are strongly magnetized. And the size of the selected stuffs, such as magnet quartz, will be less than 3000×10-6cm. It can separate a wide variety of materials from different industries in an efficient and economical manner.

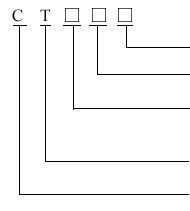

The separator is made of 4 parts: gearing, roll, tanker and economy. The roller with a wearable rover is made of stainless steel. The magnetic system which acts as an engine is put inside the roll. CX-MODEL 4 magnetic poles is designed with super magnets which enable youto deal with it easily, and with the help of handle, you can get any corner you want.

There are the refluent tanker (V), fluent tanker (S) and the half-refluent tanker(B) to choose from, the half-refluent tanker is used most widely.

The magnetic separator must match with the rule JB/T16000.

The length of the roll

The diameter of the roll

The moder of the style(N.S.B)

The magnetized roll

The magnetic system

The selection stuffs get into the tanker through the beginning box and then it well flow into the magnetic region. During this time, some powders that are strongly magnetized will be forced to the surface of the roll, at the same time, magnetism of the system from every sides will also make the magnetized stuffs moved in circle and some of waster are wiped out to make sure the rest are carried from this region. As a result of the movement the useful stuffs will flow to the end box.

| Model | Diameter × length(mm) | Magnetic intensity (GS) | Efficiency | Magnetic intensity(GS) | Efficiency | (GS) | Efficiency | Speed/ Minute | Power (kw) |

Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t/h | m3/h | t/h | m3/h | t/h | m3/h | ||||||||

| CTB-712 CTS-712 CTN-712 |

750×1200 | ≥1200 ~ 1500 | 15-30 | 48 | ≥ 1800 ~ 2100 | 20-35 | 55 | ≥ 2400 ~ 2800 | Dry 30-40 Watery 25-40 |

60 | 21-35/min | 2.2 | 1.5 |

| CTB-718 CTS-718 CTN-718 |

750×1800 | 20-35 | 72 | 20-40 | 75 | Dry 35-45 Watery 30-45 |

80 | 2 | |||||

| CTB-818 CTS-818 CTN-818 |

850×1800 | 25-40 | 100 | 31-45 | 110 | Dry 40-55 Watery 35-50 |

120 | 5.5 | 2.5 | ||||

| CTB-821 CTS-821 CTN-821 |

850×2100 | 30-50 | 130 | 35-55 | 140 | Dry 45-65 Watery 40-60 |

150 | 2.9 | |||||

| CTB-1018 CTS-1018 CTN-1018 |

1050×1800 | 40-70 | 110 | 40-60 | 120 | Dry 50-70 Watery 45-65 |

130 | 7.5 | 3.3 | ||||

| CTB-1024 CTS-1024 CTN-1024 |

1050×2400 | 50-90 | 160 | 55-100 | 170 | Dry 55-75 Watery 50-60 |

180 | 4 | |||||

| CTB-1224 CTS-1224 CTN-1224 |

1200×2400 | 70-110 | 180 | 75-120 | 190 | Dry 60-80 Watery 55-65 |

200 | 10 | 5 | ||||